It is not wrong to say that plastic products are a necessity of life for this age. From kitchen appliances, automobiles, packaging, electronics and many more countless important plastic products nowadays. There are thin, thick, hollow and complex shapes. But have you ever wondered how all these products are produced?

Plastic injection molding (plastic injection molding) is one of the process options that can be used in the production of plastic products. Although not all forms can be made through this process, I am sure more than 70% of plastic products on the market are involved in this process. Among the main advantages of this process is that it is able to produce complex plastic products, beautiful product surfaces and also a very tight dimensional range. Now we can use tablets, mobile phones, laptops, printers which are all made using plastic injection molding process and this product is very high quality.

What exactly is plastic injection molding?

Plastic injection molding (plastic injection molding) is a process in which the plastic polymer that will be included in the plastic injection molding machine (plastic injection molding machine) to be diluted until it changes shape from solid plastic polymer (usually in the form of small granules) to liquid form and finally injected into an iron mold to obtain the desired product shape.

Generally plastic injection molding machines are divided into two main units. The first unit is the injection unit while the second unit is the mold unit. In the injection unit, the plastic polymer granule will transform into a liquid after being given a high temperature between 200 ° c to reach 330 ° c depending on the type of plastic polymer used.

For example, if we use Polypropylene plastic polymer (PP) the process temperature is between 200 ° c to 240 ° c to dilute this plastic polymer. If we use Polycarbonate (PC) plastic polymer, the process temperature is between 280 ° c to 320 ° c to melt this plastic polymer. Every plastic polymer on the market has its own processing temperature. This is because of the different chain structures between these polymers.

For example, Polypropylene Polymer is from the Semi crystalline group while Polycarbonate is from the Amorphous group. Therefore, the operator of this plastic injection molding machine must have at least basic knowledge of polymers before being able to operate this machine. In fact, most plastic polymers actually need to be dried in an oven or plastic polymer dryer for a few hours before they can be used.

Otherwise the polymeric polymer plastic polymer easily absorbs moisture until it is carried into the injection unit. If this happens, the plastic products produced will have certain serious defects because the moisture carried by these non-dried plastic polymers will not be destroyed in the very hot part of the injection unit but change shape to steam until it settles inside or the surface of the resulting plastic product. Among the defects that can occur on plastic products is silver streak.

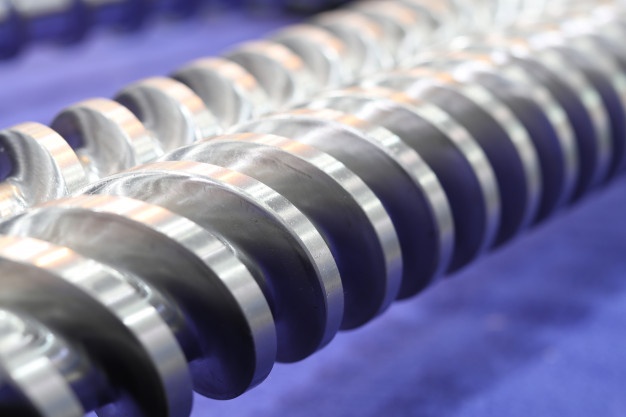

Going back to the next process for molding this plastic injection, the plastic polymer included in this hot injection unit also has a large screw unit inside. This screw will work to grind the plastic polymer granules that are inserted until fine and assisted by high temperature then the process of thawing of these granules will take place very quickly. This screw rotates counterclockwise and heads towards the back of the machine while accelerating the insertion of plastic polymer granules into the injection unit before going through the next thawing phase. When a sufficient quantity of this melted plastic polymer is in front of the screw (the total quantity of polymer in cm3 unit can be adjusted on the machine), then this plastic polymer will be injected with very high pressure and velocity into the mold and phase begins in the mold unit.

In the second unit, the mold unit, the iron mold with a certain profile will receive the injection of this molten polymer polymer in a tightly closed state with high pressure. The closing pressure rate of this mold depends on the size of the mold itself. If the mold is small then the lower the pressure of the mold should be closed and if the mold is large then the higher the pressure of the mold should be closed. The mold pressure rate can be adjusted on the machine and it is very important because the polymer injection pressure into the mold is also very high. If the closing pressure of the mold cannot accommodate the pressure pressure of this plastic polymer injection rate, then the polymer fluid will come out of the mold profile causing damage to the product. This defect we call the excess plastic (flashing). When finished all the polymer plastics are injected into the mold, this mold will go through the cooling phase.

The cooling phase of this mold will be static in the closed state until the plastic polymer changes back from liquid form to solid form. Therefore, it is obligatory for each iron mold to have a water passage in it to allow high pressure water to be pumped in and out of the mold. The purpose of this waterway works like a car engine cooling system. It ensures that the mold is always controlled and the temperature is not hot due to the continuous injection process. Temperature-controlled molds make plastic products easier to cool from liquid to solid. So the cooling time of plastic products will be faster and can increase production efficiency to the company.

Continuing from the above process, once the plastic polymer has properly – turned into a solid shape, then this mold will open. After that there is a mechanical mold system available that will push out plastic products that are still attached to the surface of the mold either to be taken by technicians or taken by robots. This process will be repeated and the rate of time required to complete a single stream of plastic injection molding process depends heavily on the size of the product itself. If the size of the plastic product is large then the required cooling phase time is also longer than the smaller plastic product.

For more information about Plastic Injection Molding Service, please visit https://www.hhmould.com/